Door Frame Making Machine

Product Details:

- Mounting Type Other

- Application Door Frame Making

- Efficiency High

- Features Robust construction Versatile usage

- Body Material

- Type Other

- Structure Horizontal frame structure

- Click to View more

Door Frame Making Machine Price And Quantity

- 800000.0 INR/Piece

- 1 Unit

Door Frame Making Machine Product Specifications

- Other

- Robust construction Versatile usage

- High

- Horizontal frame structure

- Door Frame Making

- Manufacturer warranty applicable

- Standard

- Other

Door Frame Making Machine Trade Information

- Delhi

- 5 Unit Per Month

- 15 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

Door Frame Making MachineA Door Frame Making Machine is a specialized industrial equipment designed to efficiently and accurately produce various types of door frames from raw materials. These machines are crucial in modern construction and manufacturing, automating a process that was historically labor-intensive and less precise.

The type of door frame making machine largely depends on the material being processed (metal, wood, PVC, etc.) and the desired production volume and complexity.

Common Types and Their Descriptions:

-

Metal Door Frame Roll Forming Machines (Most Common):

-

Description: These are the most prevalent type for producing steel, galvanized steel, stainless steel, or aluminum door frames. They operate on the principle of roll forming, where a continuous strip of metal is passed through a series of precisely shaped rollers. Each roller station progressively bends and forms the metal into the desired door frame profile (e.g., C-channel, Z-channel, or custom shapes for hinges and locks).

-

Working Process:

-

Decoiling/Material Feeding: A coil of sheet metal is loaded onto a decoiler, which unwinds and feeds the material into the machine.

-

Leveling/Straightening: The metal strip passes through leveling rollers to ensure it's flat and straight.

-

Punching/Notching (Optional but Common): In-line punching units create necessary holes or slots for hinges, locks, and other hardware. This can be pre-punching (before forming) or post-punching (after forming but before cutting). Advanced systems can punch intricate patterns automatically.

-

Roll Forming Stations: The core of the machine, where the metal gradually takes its final door frame shape as it moves through a sequence of roller dies.

-

Cut-off System: Once the desired length of the formed profile is achieved, a hydraulic or pneumatic cutting unit precisely severs the frame. Modern machines often use "flying cut-off" technology, where the cutter moves with the material, allowing for continuous production without stopping the roll-forming process.

-

Run-out Table/Stacker: The finished door frames are collected on a run-out table or automatically stacked for further processing or packaging.

-

-

Key Components: Decoiler, feeding guide, multiple roll forming stations with precisely machined rollers (often hardened and chrome-plated steel), hydraulic/pneumatic punching unit, hydraulic cut-off system, PLC (Programmable Logic Controller) control system, hydraulic power unit, and a run-out table.

-

Advantages: High speed, high production efficiency, consistent quality, excellent precision, reduced labor costs, and ability to handle various metal thicknesses and profiles.

-

Applications: Mass production of standard and custom metal door frames for residential, commercial, industrial, and fire-rated applications.

-

-

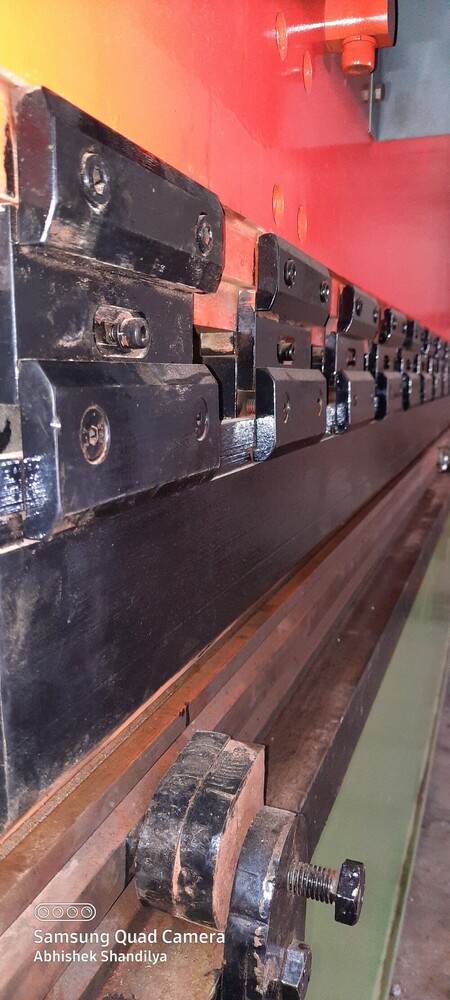

Hydraulic Press Brake Machines (for Metal Door Frames):

-

Description: While not a continuous production line like roll formers, press brakes can be used to bend individual components of metal door frames. They use a ram with a punch and a die to bend sheet metal at specific angles.

-

Working Process: Sheet metal blanks are manually or robotically placed on the die, and the ram descends to perform the bend. Multiple bends are required to create a complete door frame profile.

-

Advantages: Greater flexibility for low-volume production, custom designs, and prototyping. More cost-effective for smaller operations or specialized frames.

-

Limitations: Slower production speed, more manual handling, and less suitable for continuous, high-volume manufacturing compared to roll forming.

-

-

CNC Router Machines (for Wooden or Composite Door Frames):

-

Description: These machines use computer numerical control (CNC) to precisely cut, shape, and route wooden or engineered wood composite (e.g., MDF, WPC) materials into door frame components. They utilize rotating cutting tools (router bits) controlled by CAD/CAM software.

-

Working Process: A sheet or blank of wood/composite material is secured on the machine's bed. The CNC program directs the router head to move along X, Y, and Z axes, cutting and shaping the material according to the digital design.

-

Advantages: High precision, ability to create complex shapes and intricate designs, minimal material waste, and suitable for custom and bespoke wooden door frames.

-

Applications: Manufacturing wooden door frames, jambs, and associated trim for residential and commercial interiors.

-

-

Extrusion Machines (for Plastic/PVC Door Frames):

-

Description: Used for producing door frames from plastic materials like PVC. These machines melt plastic pellets and force the molten plastic through a die (a shaped opening) to create a continuous profile.

-

Working Process: Plastic raw material is fed into a heated barrel, melted, and then pushed through a die to form the desired cross-section of the door frame. The extruded profile is then cooled, pulled, and cut to length.

-

Advantages: Ideal for moisture-resistant frames, high production speed for continuous profiles, and cost-effective for high volumes.

-

Applications: PVC door frames, especially popular in areas with high humidity or for specific aesthetic requirements.

-

Common Features of Automated Door Frame Making Machines (especially Roll Forming):

-

PLC Control System: The "brain" of the machine, coordinating all operations (feeding speed, punching, cutting) and allowing operators to program different frame designs and quickly switch between them.

-

Touchscreen Interface: For easy operation, setting parameters, and monitoring the production process.

-

High Precision: Designed to produce frames with tight tolerances and consistent dimensions.

-

Automation: Minimizes manual labor, leading to increased output and reduced production times.

-

Robust Construction: Built with heavy-duty steel frames and high-quality components to ensure stability and durability under continuous operation.

-

Adjustable Width/Profile (for some models): Some advanced machines offer quick changeover systems or adjustable tooling to produce multiple door frame sizes or profiles on the same line.

In essence, a door frame making machine is a sophisticated solution that transforms raw materials into finished door frame components, significantly enhancing efficiency, quality, and consistency in the door manufacturing and construction industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free