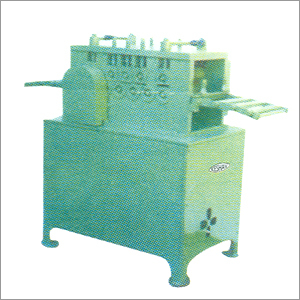

Heavy Duty Straightener

Product Details:

- Efficiency High Efficiency Hydraulic System

- Application Sheet Metal, Coil Preparation, Wire, Strip Straightening

- Accessories Control Panel, Rollers, Lubrication System

- Temperature Range 0C to 45C Operating

- Connectivity Type Standard Electrical Interface

- Mounting Type Floor Mounted

- Flow Rate Customizable as per Requirement

- Click to View more

X

Heavy Duty Straightener Price And Quantity

- 1 Unit

Heavy Duty Straightener Product Specifications

- Sheet Metal, Coil Preparation, Wire, Strip Straightening

- High Efficiency Hydraulic System

- Heavy Duty Straightener

- Variable Speed Control

- Electric

- Industrial Sealing for Oil & Dust Protection

- Customizable as per Requirement

- Standard Electrical Interface

- Floor Mounted

- High Force Output designed for Industrial Operation

- 380V/415V, 3 Phase, 50Hz

- Mild Steel

- Robust Frame Structure

- Control Panel, Rollers, Lubrication System

- 0C to 45C Operating

Heavy Duty Straightener Trade Information

- 2 Unit Per Month

- 2 Months

Product Description

Being an ISO 9001:2000 company, we are instrumental in offering high quality Heavy Duty Straightener that is used for metal punching applications in various industries. It is manufactured at our hi-tech manufacturing unit using supreme quality components with the aid of contemporary technology. Prior to dispatching the delivery from our end, this product is inspected on various parameter to ensure its flawlessness. The offered Heavy Duty Straightener is available in various technical specifications at rock-bottom prices.

Features:

-

Sturdiness

-

High-efficiency

-

Excellent strength

-

Hassle-free performance

Unmatched Heavy Duty Performance

Built with a robust frame and mild steel construction, this straightener withstands demanding industrial environments and provides consistent, high-force output for flawless straightening of sheet metal, coils, wires, and strips. Its floor mounting ensures stable operation even under heavy loads.

Tailored Solutions for Industrial Needs

The machine offers variable speed control and customizable flow rates, enabling precise adjustment to match specific operation requirements. Its industrial sealing safeguards machinery from oil and dust intrusion, enhancing durability and operational reliability for extended industrial use.

Advanced Hydraulic and Control Systems

Equipped with a high efficiency hydraulic system, this straightener delivers powerful and energy-efficient performance. The integrated control panel, specialized rollers, and lubrication system streamline the straightening process, ensuring maintenance convenience and reliable functionality.

FAQs of Heavy Duty Straightener:

Q: How does the heavy duty straightener enhance productivity in sheet metal and coil preparation?

A: With its high force output, variable speed control, and robust hydraulic system, the straightener efficiently flattens and aligns sheet metal and coils. This accelerates preparation processes, minimizes material defects, and supports uninterrupted production rates in industrial environments.Q: What are the benefits of the industrial sealing feature for oil and dust protection?

A: Industrial-grade sealing protects internal components from oil and dust contamination, reducing maintenance needs and extending machine lifespan. This ensures sustained accuracy and reliability, even in harsh or demanding factory settings.Q: When is variable speed control most advantageous during operation?

A: Variable speed control is crucial when dealing with different material types, thicknesses, or when processing jobs that require precision. It allows operators to optimize throughput and quality by selecting speeds tailored to each specific straightening requirement.Q: Where is the straightener typically installed, and why is mounting important?

A: This straightener is designed for floor mounting in manufacturing plants, ensuring stability during high-force operations. Secure installation prevents vibration and misalignment, which are essential for achieving precise straightening results.Q: What is the process for customizing the flow rate of the straightener?

A: Flow rates can be tailored during installation or as per operational needs. The machines hydraulic system allows users to adjust settings via the control panel, enabling smooth adaptation to varying production demands and material characteristics.Q: How do the included accessories improve usage and maintenance of the straightener?

A: Accessories like the control panel, rollers, and lubrication system simplify operation and upkeep. The control panel offers intuitive operation, rollers ensure uniform straightening, and the lubrication system reduces wear, promoting safer and prolonged use.Q: What makes the straightener suitable for high-volume industrial applications in India and abroad?

A: Its robust build, high efficiency hydraulic system, and adaptability to different voltage standards enable reliable performance in diverse industrial settings. Designed for export, the straightener supports heavy-duty functions and meets global operational requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free