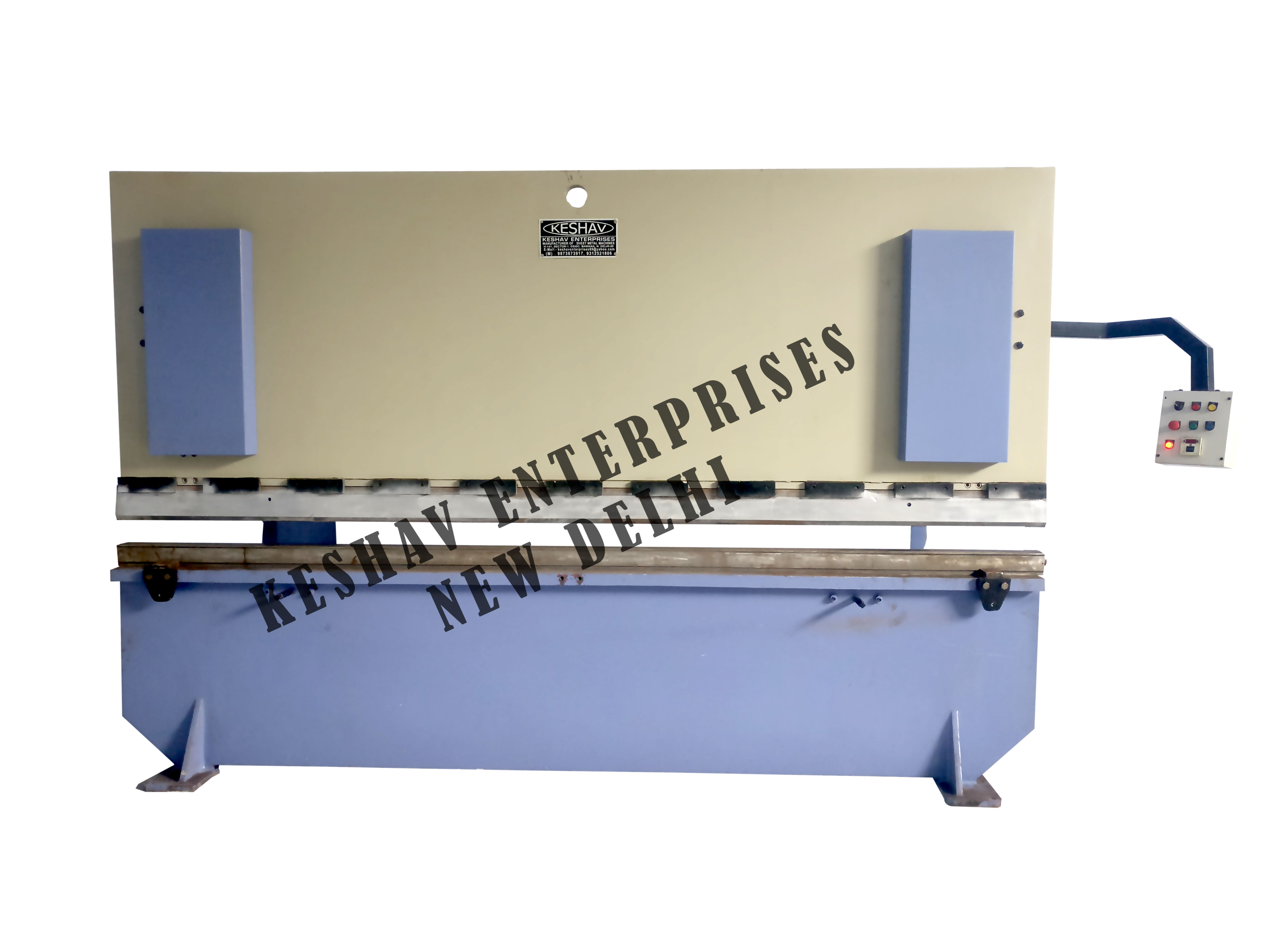

Press Brake

350000.00 INR/Piece

Product Details:

- Application Sheet Metal Bending, Fabrication Workshops, Industrial Manufacturing

- Efficiency High Efficiency

- Mounting Type Floor Mounted

- Connectivity Type Wired

- Temperature Range 5C to 45C

- Flow Rate 12 L/min

- Features Digital Readout, Adjustable Stroke, Precision Machining, Emergency Stop

- Click to View more

X

Press Brake Price And Quantity

- 1 Piece

- 350000.00 INR/Piece

Press Brake Product Specifications

- 415 V

- Floor Mounted

- 8 mm/s (bending), 60 mm/s (return)

- Wired

- Mild Steel

- 5C to 45C

- Sheet Metal Bending, Fabrication Workshops, Industrial Manufacturing

- 60 Tons

- High Efficiency

- Hydraulic Press Brake

- Electric

- Dual Seal Cylinder

- 250 bar

- Back Gauge, Foot Switch, Tooling Set

- Welded Steel Frame

- 12 L/min

- Digital Readout, Adjustable Stroke, Precision Machining, Emergency Stop

Press Brake Trade Information

- 2 Piece Per Month

- 2 Months

Product Description

We are the foremost manufacturer, exporter and supplier of Press Brake that is widely appreciated in the market due to its optimum performance and high efficiency. It is manufactured at our well-equipped manufacturing unit using premium grade metal alloy under the supervision of diligent professionals. ailable in capacity of 50 to 500 Tons and is used in diverse areas of automobile industry. Our clients can avail this Press Brake at rock-bottom prices.

Features:

- Optimum performance

- Long functional life

- Robust design

- Low maintenance

Superior Build and Performance

Constructed with a welded mild steel frame, this press brake offers exceptional rigidity and stability. The hydraulic system ensures consistent 60-ton force delivery, allowing smooth operation with precise control over bending speeds and strokes. Its high efficiency and robust performance make it well-suited for industrial-scale projects.

Advanced Features for Enhanced Precision

Equipped with digital readout and adjustable stroke, the press brake enables accurate angle control and repeatability during sheet metal bending. Emergency stop systems enhance operational safety, while versatile mounting and a dual seal cylinder design minimize maintenance requirements.

Versatility For Modern Workspaces

This hydraulic press brake is suitable for a wide range of applications from custom fabrication to heavy-duty industrial manufacturing. Accessories like back gauge, foot switch, and tooling set streamline workflow, meeting the demands of professional fabrication environments in India and worldwide.

FAQs of Press Brake:

Q: How does the dual seal cylinder enhance the performance of this hydraulic press brake?

A: The dual seal cylinder reduces leakage and improves hydraulic integrity, ensuring consistent operating pressure and reliable performance during continuous sheet metal bending tasks.Q: What materials and thicknesses can be bent using this press brake?

A: With a 60-ton force and robust welded steel frame, the press brake is well-suited for bending a variety of sheet metalsprimarily mild steelin fabrication and industrial workshops, depending on specific tooling and material thickness requirements.Q: When is it most beneficial to use the digital readout feature?

A: The digital readout is particularly valuable during setup and repetitive bending projects, allowing operators to precisely monitor and replicate angle settings for consistent, high-quality results.Q: Where can this press brake be installed?

A: Designed as floor mounted equipment, this machine is ideal for fabrication shops, industrial manufacturing units, and workshops that require stable, large-format sheet metal bending capabilities.Q: What is the process for operating the hydraulic press brake safely?

A: Begin by setting up workpieces using the back gauge and tooling set, adjust the stroke as needed, and monitor the process via digital readout. Operators should engage the emergency stop in case of unusual incidents to ensure safety at all times.Q: How does the adjustable stroke feature increase operational flexibility?

A: Adjustable stroke allows for fine-tuning the bending depth, making it possible to handle a wide variety of part geometries and reducing cycle times, especially during custom or complex fabrication tasks.Q: What are the key benefits of using this hydraulic press brake in industrial manufacturing?

A: Key benefits include high precision bending, robust construction, efficient electric-hydraulic operation, safety features, and enhanced productivity through modern accessoriesall catering to reliable, large-scale sheet metal work.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free