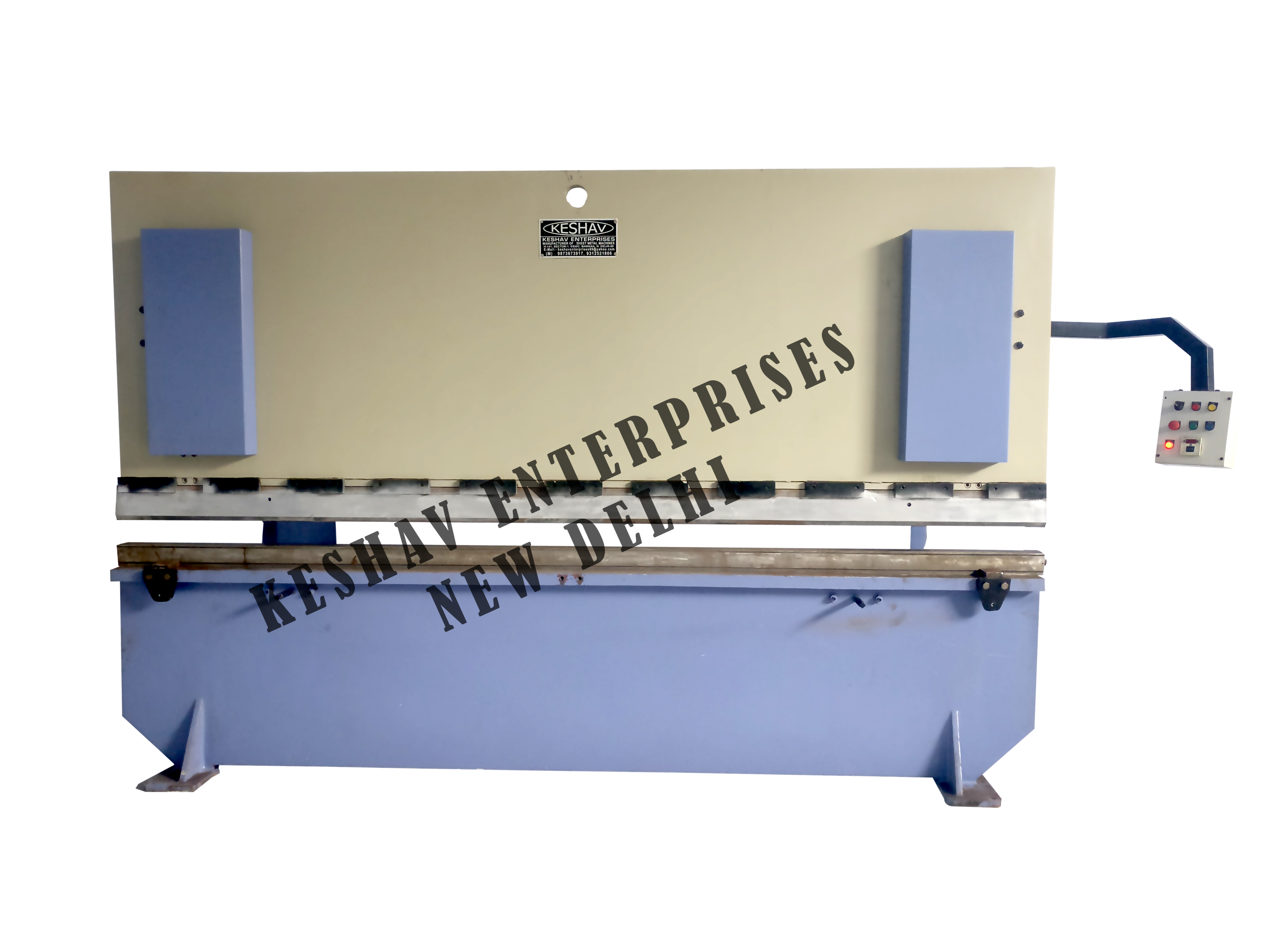

Back Cylinder Hydraulic Bending Machine

Product Details:

- Temperature Range -10C to +60C

- Mounting Type Floor mounted

- Application Sheet metal bending for industrial fabrication and engineering

- Sealing Type High-pressure hydraulic seals

- Flow Rate 35-80 L/min

- Operating Pressure 16-25 MPa

- Power Source Electric - Hydraulic motor

- Click to View more

X

Back Cylinder Hydraulic Bending Machine Price And Quantity

- 1 Unit

Back Cylinder Hydraulic Bending Machine Product Specifications

- Floor mounted

- -10C to +60C

- High-pressure hydraulic seals

- 60-3200 kN (variable options)

- 380V/415V/440V (3 phase, 50/60Hz)

- Sheet metal bending for industrial fabrication and engineering

- Back Cylinder Hydraulic Bending Machine

- High-grade steel

- 5-20 mm/s (adjustable bending speed)

- Standard punch and die set, foot switch, hydraulic oil tank

- 16-25 MPa

- 35-80 L/min

- PLC control panel with user interface

- Electric - Hydraulic motor

- High production efficiency (>85%)

- Welded steel frame with heavy-duty reinforcement

- Programmable control, precision bending, anti-corrosive coating, overload protection

Back Cylinder Hydraulic Bending Machine Trade Information

- 2 Unit Per Month

- 2 Months

Product Description

Experience the peerless performance of our new Back Cylinder Hydraulic Bending Machine, designed for pristine precision in industrial fabrication. Engineered with a welded steel frame and heavy-duty reinforcement, this opulent machine offers a maximum bending length of up to 4000 mm and handles thicknesses from 0.5 mm to 14 mm. Featuring advanced programmable control, digital LCD accuracy (0.01 mm), and CE-certified robust safety, it ensures high production efficiency. Secure your advance purchase for a reliable, anti-corrosive, and technologically superior bending solution.

Versatile Usage & Advanced Features

The Back Cylinder Hydraulic Bending Machine is tailored for robust industrial fabrication tasks, including engineering and sheet metal bending. With programmable PLC controls, digital precision, overload protection, and a pristine powder-coated finish, this machine supports both custom and high-volume production needs. It is trusted for its opulent anti-corrosive construction, advanced safety features, and seamless integration with standard punch, die sets, and user-friendly foot switches, ensuring optimal usage efficiency.

Export Markets, Payment & Sample Policy

We hand over our Back Cylinder Hydraulic Bending Machines to major export markets including Asia, Africa, and Europe at the lowest price points. Our clear payment terms and flexible sample policy ensure a smooth handover process. Clients can request samples under our policy, enabling confident decisions before placing bulk orders. Rely on timely delivery and dependable after-sales support for every transaction, facilitating a peerless equipment handover experience worldwide.

Versatile Usage & Advanced Features

The Back Cylinder Hydraulic Bending Machine is tailored for robust industrial fabrication tasks, including engineering and sheet metal bending. With programmable PLC controls, digital precision, overload protection, and a pristine powder-coated finish, this machine supports both custom and high-volume production needs. It is trusted for its opulent anti-corrosive construction, advanced safety features, and seamless integration with standard punch, die sets, and user-friendly foot switches, ensuring optimal usage efficiency.

Export Markets, Payment & Sample Policy

We hand over our Back Cylinder Hydraulic Bending Machines to major export markets including Asia, Africa, and Europe at the lowest price points. Our clear payment terms and flexible sample policy ensure a smooth handover process. Clients can request samples under our policy, enabling confident decisions before placing bulk orders. Rely on timely delivery and dependable after-sales support for every transaction, facilitating a peerless equipment handover experience worldwide.

FAQs of Back Cylinder Hydraulic Bending Machine:

Q: How does the programmable control enhance the machines operation?

A: The programmable PLC control offers precise bending capabilities, allowing users to set customized parameters for consistent and repeatable results. This ensures accurate sheet metal fabrication with minimal manual intervention.Q: What materials can the Back Cylinder Hydraulic Bending Machine handle?

A: This machine is suitable for bending a wide range of sheet metals, including steel, aluminum, and other industrial metals, ranging from 0.5 mm to 14 mm in thickness.Q: Where is the Back Cylinder Hydraulic Bending Machine primarily used?

A: It is predominantly used in industrial fabrication settings such as manufacturing plants, sheet metal workshops, and engineering facilities for high-precision bending applications.Q: What safety features are included in the machine?

A: The machine is CE certified and equipped with essential safety measures including an emergency stop button, overload protection, and high-pressure hydraulic seals, ensuring operator safety during use.Q: What are the main benefits of choosing this machine for fabrication?

A: Key benefits include high production efficiency (over 85%), pristine and anti-corrosive construction, advanced digital controls, versatile bending capabilities, and a robust structure ensuring long-term reliability.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS