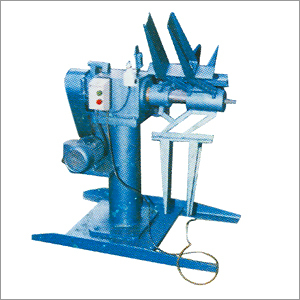

Industrial Heavy Duty Decoiler

Product Details:

- Application Coil Feeding in Press Shop, Roll Forming Lines, Sheet Metal Processing

- Connectivity Type Panel Wired/Remote Control

- Features Hydraulic Expansion, Coil Car Option, Electronic Brake System, Operator Safety Features

- Flow Rate Customizable as per application

- Mounting Type Floor Mounted

- Sealing Type Dust Proof Sealed Bearing

- Accessories Coil Car, Separator Disc, Hydraulic Power Pack, Remote Control

- Click to View more

X

Industrial Heavy Duty Decoiler Price And Quantity

- 1 Unit

Industrial Heavy Duty Decoiler Product Specifications

- Customizable as per application

- High Load Bearing Capability

- Hydraulic Expansion, Coil Car Option, Electronic Brake System, Operator Safety Features

- Dust Proof Sealed Bearing

- Floor Mounted

- Coil Car, Separator Disc, Hydraulic Power Pack, Remote Control

- Electric Motor Driven

- Heavy Duty Industrial Decoiler

- Coil Feeding in Press Shop, Roll Forming Lines, Sheet Metal Processing

- Robust Welded Frame

- Mild Steel

- Panel Wired/Remote Control

- Adjustable via Variable Frequency Drive (VFD)

Industrial Heavy Duty Decoiler Trade Information

- 2 Unit Per Month

- 2 Months

Product Description

With the support of our dextrous professionals, we are able to manufacture, export and supply Heavy Duty Decoiler. It is manufactured in compliance with the set industry norms using premium quality components under the observation of skilled professionals. The offered product is tested on various parameters by our quality controllers to ensure high performance at clients' end. This Heavy Duty Decoiler is available at industry leading prices.

Features:

-

Excellent performance

-

Low maintenance

-

Robust design

-

Long service life

Robust Construction for Demanding Tasks

Built with a rugged welded mild steel frame, this decoiler is designed to endure heavy industrial loads and frequent use. Its high load-bearing capability and dust-proof sealed bearings ensure longevity, minimal maintenance, and consistent performance. The floor-mounted structure further guarantees stability during high-speed coil feeding operations.

Advanced Control and Safety Features

Equipped with an electric motor, hydraulic expansion, electronic brake system, and a variable frequency drive (VFD), the decoiler offers precise speed control and efficient coil handling. Operator safety features and remote control options enable convenient and secure operation within dynamic production environments.

Versatile Application and Customization

The decoiler is suitable for coil feeding in press shops, roll forming lines, and sheet metal processing units. The customizable flow rate, coil car accessory, separator disc, and panel-wired or remote connectivity allow seamless integration and flexibility for varied industrial workflows.

FAQs of Industrial Heavy Duty Decoiler:

Q: How does the variable frequency drive (VFD) enhance decoiler speed control?

A: The VFD allows operators to adjust the speed of the decoilers electric motor with precision, ensuring optimal coil feeding rates for different materials and applications. This feature helps improve process efficiency and minimizes material waste.Q: What are the main safety features integrated into the heavy duty industrial decoiler?

A: The decoiler includes operator safety features such as an electronic brake system, dust-proof sealed bearings to reduce exposure to moving parts, and remote control operation. These safeguards help protect personnel and ensure secure, accident-free functioning.Q: When is hydraulic expansion used in this decoiler?

A: Hydraulic expansion is activated during coil loading to securely grip and center coils of various dimensions. This mechanism simplifies the coil handling process and reduces downtime during changeovers, enhancing throughput.Q: Where is this robust industrial decoiler typically installed?

A: This decoiler is floor-mounted, usually positioned in press shops, roll forming lines, and sheet metal processing facilities. Its stable structure is ideal for environments requiring reliable coil feeding operations.Q: What process does the decoiler support in industrial settings?

A: It facilitates the unwinding and feeding of metal coils into presses, roll formers, or sheet metal processing machines. The adjustable flow rate and optional coil car accessories optimize the material supply process, promoting consistent production cycles.Q: What are the primary benefits of using this heavy duty decoiler?

A: Users benefit from enhanced operational reliability, customizable material handling, improved safety, and reduced maintenance needs. The systems advanced features result in smoother workflow, increased productivity, and adaptability for varied industrial applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS