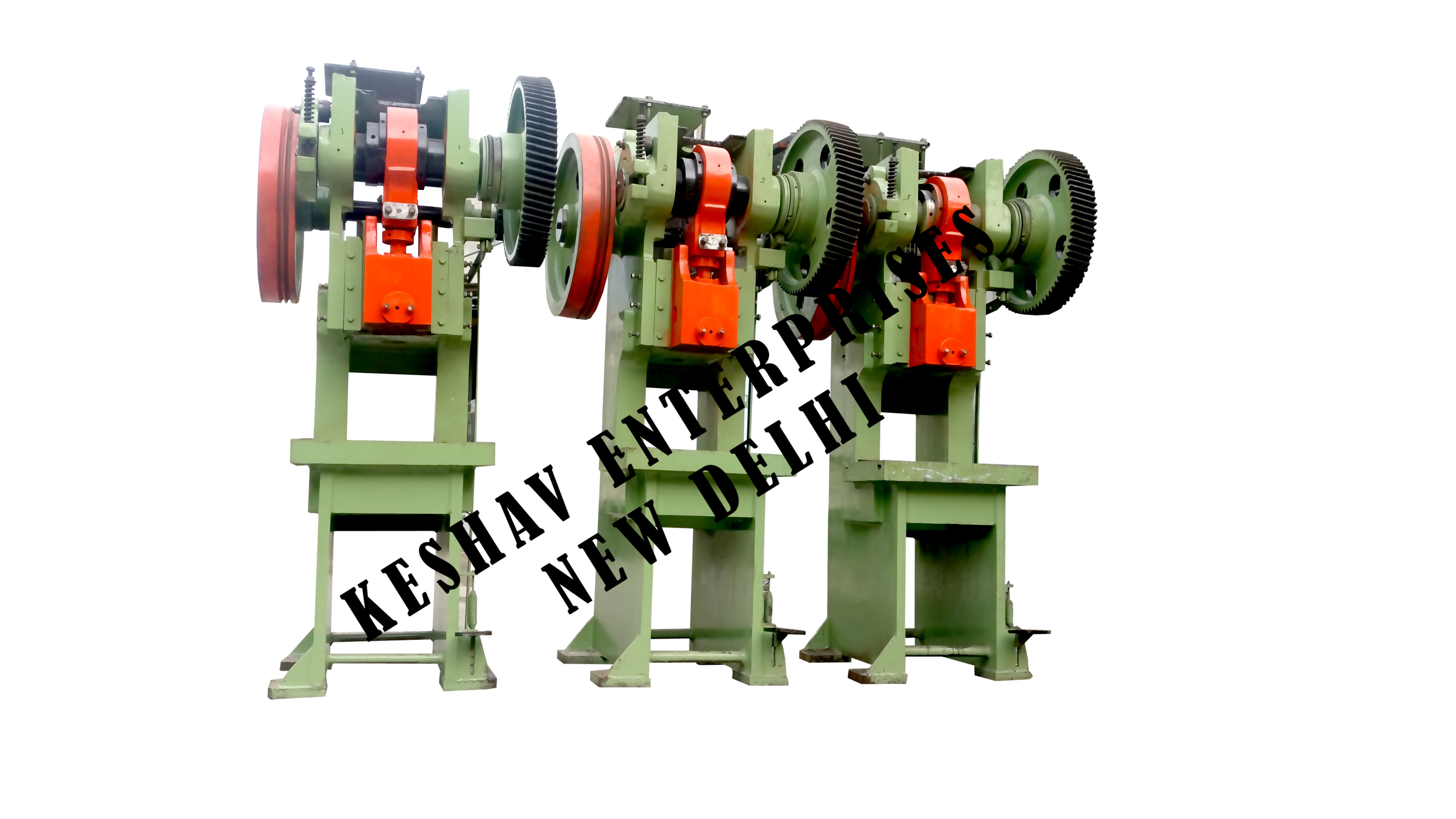

Non Inclinable Power Press

300000 INR/Piece

Product Details:

- Operating Pressure Hydraulic or Mechanical (Model dependent)

- Mounting Type Floor Mounted

- Sealing Type Heavy Duty Gasket/Seal

- Temperature Range Ambient to 50C

- Power Source Electric Motor Driven

- Flow Rate Standard as per Power Pack (hydraulic models)

- Application Sheet Metal Forming, Stamping, Punching, Blanking operations

- Click to View more

X

Non Inclinable Power Press Price And Quantity

- 300000 INR/Piece

- 1 Piece

Non Inclinable Power Press Product Specifications

- Floor Mounted

- Heavy Duty Gasket/Seal

- Hydraulic or Mechanical (Model dependent)

- Cast Iron

- 10 to 250 Tons (varies as per model)

- 415 V, Three Phase, 50 Hz

- Manual/Electrical Controls

- Die cushion, Electrical control panel, Hand lever controls, Foot pedal

- Sheet Metal Forming, Stamping, Punching, Blanking operations

- Rigid Frame

- Standard as per Power Pack (hydraulic models)

- Electric Motor Driven

- Ambient to 50C

Non Inclinable Power Press Trade Information

- 2 Piece Per Month

- 2 Months

Product Description

Non Inclinable Power Press

Being an 100% export oriented company, we are strictly engaged in offering premium quality Non Inclinable Power Press that is highly appreciated across the globe for its optimum performance. It is manufactured in compliance with the set industry standards using finest grade components at our state-of-the-art manufacturing unit. In ahead of dispatching the delivery from our end, this product is tested thoroughly on various parameters to ensure its flawlessness. This offered Non Inclinable Power Press is available at nominal prices.

Features:

- Sturdy construction

- Long service life

- Smooth operation

Technical Specification

| Model | K-20 | K-30 | K-40 | K-50 | K-60 | K-80 | K-100 | K-125 | K-160 |

| Capacity in tones | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 125 | 160 |

| Stroke adjustable standard (mm) | 8-50 | 8-63 | 8-80 | 8-80 | 8-100 | 8-100 | 8-125 | 8-125 | 20-160 |

| Shut-Height Standard (mm) | 225 | 250 | 280 | 280 | 315 | 315 | 355 | 355 | 400 |

| Throat Standard (mm) | 180 | 210 | 230 | 230 | 260 | 260 | 325 | 325 | 325 |

| Clear distance between Upright (mm) | 330 | 330 | 365 | 370 | 400 | 465 | 465 | 500 | 525 |

| Slide Adjustment (mm) | 50 | 50 | 63 | 63 | 63 | 63 | 80 | 80 | 100 |

| Bed Area-Standard (mm) | 355x560 | 400x630 | 450x710 | 500x800 | 500x900 | 630x900 | 630x900 | 630x1000 | 630x1000 |

| Height of Bolster face Floor (mm) | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 |

| Stroke per minute (No.) | 60 | 50 | 45 | 50 | 45 | 45 | 45 | 40 | 35 |

| Motor (HP/1400 x rpm) | 3 | 3 | 5 | 7.5 | 7.5 | 10 | 12.5 | 12.5 | 15 |

Superior Construction for Lasting Performance

Crafted with a sturdy cast iron body and a rigid frame, the Non Inclinable Power Press is built to withstand demanding operations. Whether you require hydraulic or mechanical models, each press ensures long-lasting efficiency, minimal vibration, and reliable functionality in continuous production environments.

Versatile Application in Metalworking

This press is highly adaptable for various sheet metal working tasks, including forming, punching, stamping, and blanking. Its multiple force options allow users to select a model tailored precisely to their material thickness and job requirements, making it a preferred choice for fabricators and manufacturers alike.

Advanced Safety and Control Features

To enhance operator safety and precision, the power press features comprehensive control options such as hand levers, foot pedals, and an advanced electrical control panel. Heavy-duty gaskets and secure seals are fitted to all hydraulic variants, ensuring minimal leakage and safer operation throughout its use.

FAQs of Non Inclinable Power Press:

Q: How does the Non Inclinable Power Press operate, and what are its primary applications?

A: The Non Inclinable Power Press operates using an electric motor and offers both hydraulic and mechanical drive systems, varying by model. It is primarily used for sheet metal forming, stamping, punching, and blanking operations in manufacturing and fabrication environments.Q: What body material and structural features ensure its durability during heavy-duty use?

A: With a solid cast iron body and rigid frame, the power press offers superior resistance to wear and deformation. These construction features provide stability and strength even during high-force applications, ensuring extended operational life and consistent performance.Q: When should I choose a hydraulic model over a mechanical one?

A: Hydraulic models are ideal when you require smoother operation, controlled force, and variable speed, especially for complex or precision tasks. Mechanical models are more suited for high-speed, repetitive operations where consistent force and faster cycling are paramount.Q: Where can the Non Inclinable Power Press be installed, and what is its mounting type?

A: This power press is designed for floor mounting, making it suitable for installation in industrial workshops, fabrication units, or manufacturing plants where stable, permanent placement is essential for safety and efficiency.Q: What accessories and safety features are included with the machine?

A: Standard accessories include a die cushion for enhanced material support, an electrical control panel for operational control, hand lever controls, and a foot pedal. All models also feature heavy-duty seals to prevent leaks and improve safety during hydraulic operation.Q: How can operators control and monitor the press during operation?

A: Operators can manage the press using manual hand levers or a foot pedal for direct control, while advanced electrical control panels facilitate monitoring and adjusting operational settings easily for increased precision and safety.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

CAll Us :-

CAll Us :-  keshaventerprises89@yahoo.com

keshaventerprises89@yahoo.com

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free